How To Install ACP Sheet Properly: Step By Step Guide & Benefits

In today's architecture and construction world, ACP sheets are essential for buildings. They're strong, flexible, and look great, making them perfect for adding style and protection to structures. However, to ensure ACP panels do their job properly, they need to be installed correctly.

So in this guide, we'll take a deep dive into how to install ACP sheets the right way, from getting everything ready to adding those final touches. You will know exactly what to do to make those ACPs shine.

Preparation

Before you start putting up ACP sheets, it's important to get everything ready. First, check the area where you're installing. The area must be clean and in good shape. Fix any problems with the surface so it's nice and smooth for the ACP panels to stick to.

Also, double-check the size and layout of the sheets. Look at it to match up with the plans for the building. You don't want any surprises later on! So, take your time to prep the area properly before you begin installing the ACP sheets.

Tools and Materials

Get together all the stuff you'll need for putting up the ACP sheets. This includes things like a measuring tape, a level to make sure everything's straight, a drill, a rivet gun, silicone sealant, and adhesive tape. And don't forget safety tools like gloves and goggles.

Make sure you've got enough ACP sheets, along with all the screws, rivets, and sealant you'll need to finish the job without having to stop. One must be prepared ahead of time instead of lacking supplies.

Step By Step ACP Sheet Installation Process

1. Panel Layout

Begin by laying out the ACP panels according to the predetermined design and orientation. Take accurate measurements and mark the positions for panel placement to maintain symmetry and alignment.

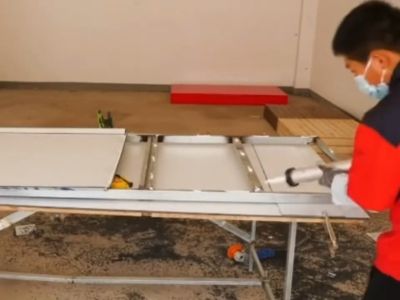

2. Cutting and Fabrication

Use appropriate cutting tools such as a circular saw or router to trim the ACP sheets to the required dimensions. Exercise caution and precision to achieve clean and accurate cuts, ensuring a seamless fitting.

3. Attachment

Secure the ACP panels to the substrate using mechanical fasteners or adhesive bonding, depending on the specific requirements of the project. Ensure that fasteners are evenly spaced and run flush with the surface to prevent unevenness.

4. Joint Sealing

Apply a silicone sealant along the edges and joints of the ACP panels to create a watertight seal and prevent moisture infiltration. Smooth the sealant with a putty knife or caulking tool to achieve a neat and uniform finish.

5. Finishing Touches

Once the ACP panels are securely installed and sealed, inspect them to prevent any imperfections or gaps. Make any necessary adjustments or touch-ups to ensure a flawless appearance and optimal performance.

Safety Precautions

Make sure to stay safe while you're putting up the ACP sheets. Wear gloves, goggles, and a mask to protect yourself from any dust or fumes. Be careful when you're using sharp tools or power equipment, and make sure everything is securely fastened to avoid accidents.

Also, work in a space with good airflow, and follow the instructions carefully to avoid any mishaps. It's better to take your time and be safe than to rush and risk getting hurt.

Maintenance and Care

Once you've got the ACP sheets up, it's important to keep them in good shape. Check them regularly for any damage or wear, and fix any problems right away to stop them from getting worse.

To keep the panels looking nice, clean them every so often with some soap and water to get rid of any dirt or grime. This helps them stay looking fresh and new for longer.

6 Benefits of Proper ACP Sheet Installation

1. Enhanced Durability

Proper installation ensures that ACP sheets are securely attached to the substrate, minimizing the risk of damage or detachment due to external factors.

2. Improved Aesthetic Appeal

Well-installed ACP panels provide a seamless and uniform appearance, enhancing the aesthetic appeal of buildings.

3. Structural Integrity

Adequate attachment and support of ACP panels contribute to the structural integrity of the building.

4. Weather Resistance

A properly installed ACP cladding system offers superior weather resistance, protecting the underlying structure from moisture infiltration, UV radiation, and temperature fluctuations.

5. Energy Efficiency

Effective insulation and sealing of ACP cladding mitigate fluctuations in internal temperatures caused by external weather variations, ultimately enhancing energy efficiency within the building.

6. Regulatory Compliance

Following proper ACP sheet installation procedures ensures that ACP cladding meets relevant building codes, standards, and regulations.

Conclusion

To wrap things up, getting the ACP sheets installed right is super important for making the most of their advantages in building projects. By sticking to the steps we've covered in this guide, you can ensure the installation goes smoothly. That means you'll end up with ACP cladding that not only looks great but also lasts long and holds up well against the elements.

Frequently Asked Questions:

What is the cost of ACP sheet installation?

The cost of ACP sheet installation varies depending on the region, brand, and complexity of the project. On average, installation costs range from ₹200 to ₹400 per square foot in India. This includes material, labor, and other expenses. Prices may vary based on customization and design complexity.

What is the lifespan of the ACP Panel?

ACP panels typically have a lifespan of 15 to 20 years. With proper maintenance, they can last even longer. Their durability depends on factors like the environment, installation quality, and whether they are exposed to harsh weather conditions or pollutants, which may affect its longevity.

How are ACP sheets fixed to the wall?

ACP sheets are fixed to walls using a framework of aluminum or steel. The sheets are fixed with screws, rivets, or adhesives, depending on the installation method. They are then adjusted for alignment, and the joints are sealed to ensure a smooth and weather-resistant finish.

Leading ACP Sheet Manufacturer

As a proud representative of Alumina ACP, a premier manufacturer of Aluminum Composite Panels, I bring a wealth of expertise in acp sheets and addressing diverse architectural needs with innovative solutions. Join me on this journey of exploration and discovery!